Email cannot be empty

Password cannot be empty

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Acrylic Sealant Production Line

-

≥1/set

USD 150,000.00

Acrylic sealants are widely used in construction, DIY projects, and industrial applications due to their excellent adhesion, flexibility, and water resistance. Unlike silicone sealants, they are paintable and have lower VOC emissions. Below, we explore the key materials and production steps involved in manufacturing acrylic sealants.

1. Raw Materials for Acrylic Sealant

The formulation of acrylic sealants includes:

Base Components

-

Acrylic polymer emulsion (primary binder, provides adhesion & flexibility)

-

Fillers (e.g., calcium carbonate, talc, or silica for viscosity and strength)

-

Plasticizers (improve flexibility and workability)

Additives & Modifiers

-

Thickeners (e.g., cellulose ether or polyacrylate for desired consistency)

-

Defoamers (prevent air bubbles during mixing)

-

Preservatives (extend shelf life)

-

Pigments (for color, e.g., titanium dioxide for white sealant)

-

UV stabilizers (for outdoor-grade sealants)

Solvents (if solvent-based)

-

Water (for water-based acrylic sealants)

-

Organic solvents (for solvent-based variants, less common today)

2. Production Process of Acrylic Sealant

Step 1: Pre-Mixing

-

Raw materials (polymer emulsion, fillers, and additives) are weighed and pre-dispersed in a high-speed disperser.

-

Ensures uniform distribution before final mixing.

Step 2: High-Shear Mixing

-

The pre-mixed batch is transferred to a planetary mixer or high-shear mixer.

-

Vacuum may be applied to remove air bubbles for a smooth texture.

Step 3: Adjusting Consistency & Properties

-

Thickeners and plasticizers are added to achieve the desired viscosity.

-

Defoamers prevent foam formation during mixing.

-

Pigments & UV stabilizers are incorporated for color and durability.

Step 4: Quality Control Testing

-

Viscosity (using a viscometer)

-

Adhesion strength (peel tests on substrates like wood, concrete, or metal)

-

Curing time & elasticity (ensures proper performance)

Step 5: Filling & Packaging

-

The finished sealant is pumped into:

-

Cartridges (for handheld caulking guns)

-

Tubes or buckets (for larger applications)

-

-

Automated capping and labeling machines seal and mark the product.

3. Types of Acrylic Sealants

| Type | Features | Common Uses |

|---|---|---|

| Water-Based | Low odor, easy cleanup, eco-friendly | Indoor joints, drywall, painting prep |

| Solvent-Based | Stronger adhesion, water-resistant | Outdoor applications, metal/wood sealing |

| Elastomeric Acrylic | High flexibility, crack-bridging | Expansion joints, concrete repairs |

Advantages Over Other Sealants

✔ Paintable – Unlike silicone, acrylic sealants can be painted after curing.

✔ Low VOC – Water-based versions are more eco-friendly.

✔ Good Adhesion – Bonds well to porous materials (wood, concrete, plaster).

✔ Cost-Effective – Generally cheaper than silicone or polyurethane sealants.

TGM Chemical Machine Co., Ltd is a group enterprise. We have brands like TGM, Pengchang and Tongpeng.

We are a leader in the field of chemical machine industry, with 18 years of industry experience.

We have professional R&D design team, strong technical support, skilled production team, reliable after sales service, flexible customized solutions,

to meet your various standards and non standard equipment procurement needs. We committed to providing the complete and professional chemical equipment solutions.

We integrate, design, development, production, sales and training together.

Our products scope: Disperser, Bead Mill, Basket Mill, Mixer, emulsifier, Mixing kettles, Reactor, Filling machine, Bag filter, Pumps, Zirconium Bead, 3 roll mill, and other accessories.

Our machines help you to make ideal products: paints, coatings, inks, pigments, dyes, thinner, hardener, emulsions, varnish, spin finish, putty, glues, adhesives, viscous pastes, concrete Admixtures,

PCVC solvent cement, liquid resins, sealants, silicone sealant, lithium battery, electronic slurry&paste, pulps, silicon dioxide, liquid rubber, pesticide, liquid fertilizer, disinfectant, liquid detergent, gel,

lotions, shampoo, body wash, liquid soap, hand sanitizer, liquid wash, nail polish, creams, and so on.

We could offer individual machine or full production lines for your plants.

5. What are advantages of your factory?

1) Our factory is a leader manufacture of Chemical machine With 18 years of Industry experience. We have a lot Technology Patents & Product Patents;

2) Our factory has Professional R&D Teams, High Technical Supports, Skilled Production Team, Reliable After Sales Service, Flexible Customized Solutions;

3) Our factory is the leader of this industry, named with high and new technology enterprise;

4) Our factory has plenty of industry experience, we could offer you the complete palnt planning.

6. Who are your factory's clients? Could you list some of them?

AKZONOBEL, JUNTON, PPG, NIPPON, DABAO, BURGER, MAYDOS, RAINBOW, HITECH COATING, CHINA PAINT, CHANGJIANG COATING, TOA, LYNWON PIGMENT,

PEONY INKS, TL INKS, ZR INKS, SAKATA INKS, KINGSWOO INKS, DIC INKS, ANLI, ACHILLES, REPOW GROUP, SHINETSU ADHESIVES, JUSHI, XINGLONG PESTICIDES...

7. What certificate your factory could offer?:

CE, BSC, CNEX, ISO, patents.

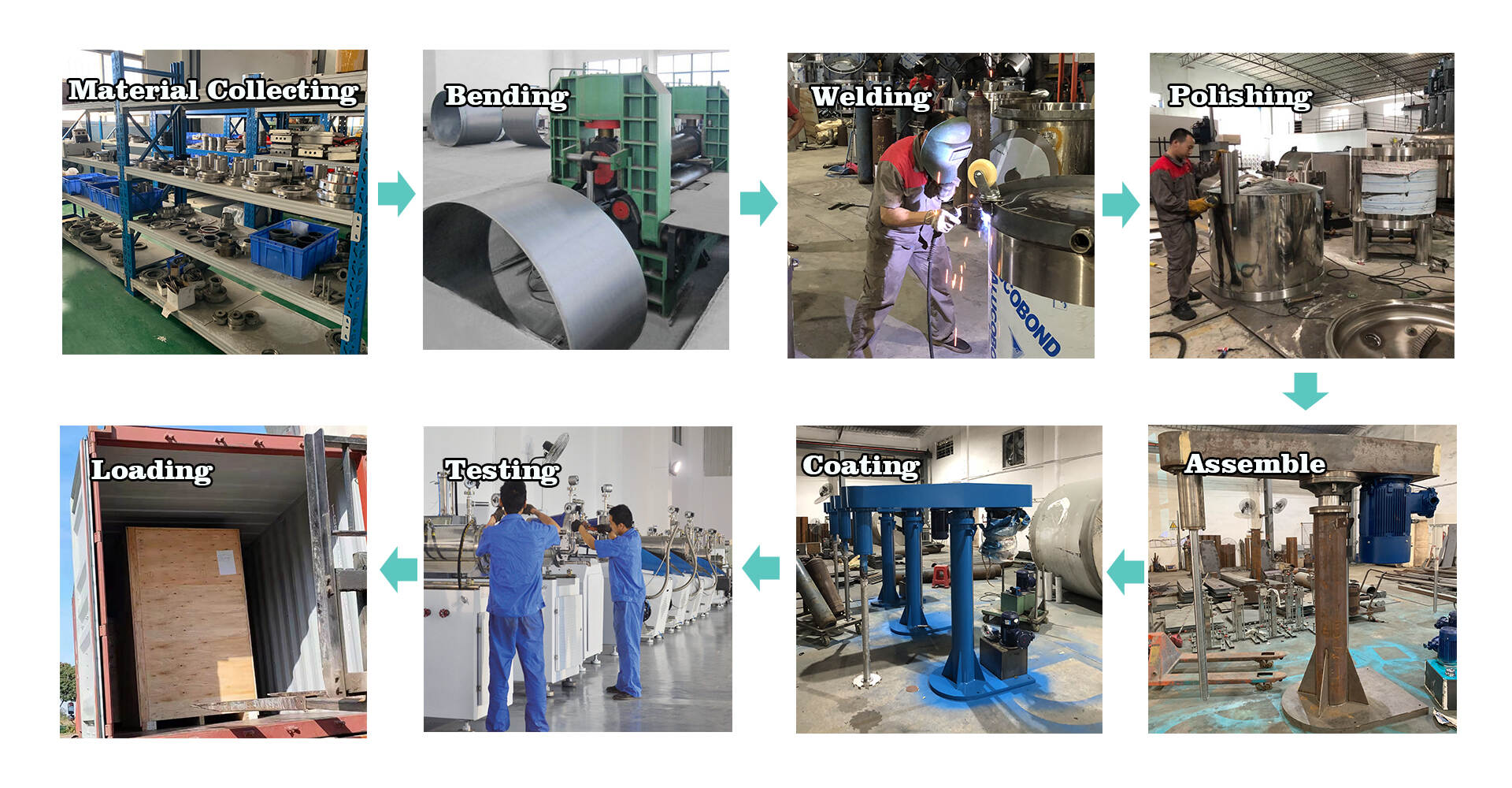

8. Manufacture Processing:

Our Chemical Machines are strictly quality control at every single production step, after quality past, we will move to do next step production.

Our Chemical Machines production process: raw materials preparing-cutting/bending materials-welding-polishing-assembling-coating-testing-packing-loading.

9. Packing And Shipping:

10. FAQ:

Question: Are you a factory or a trading company? where is your factory?

Answer: We are a real factory. Our factory is in fu'an industrial zone, leliu street, shunde ditrict, foshan city, guangdong province, China.

Question: Which countries your machine sold to?

Answer: American Market: America, Canada, Mexico, Brazil;

European Market: UK, Germany, Netherlands, Bulgaria, Italy, Russia;

African Market: South Africa, Algeria, Zambia, Cameroon, Ethiopia, Uganda, Madagascar;

Asian Market: Malaysia, Indonesia, Singapore, Vietnam, Thailand, Kazakhstan, Bangladesh, Pakistan, Lebanon, Iran, Iraq, Egypt, Qatar, Turkey, Saudi Arabia, UAE;

Question: How long is your machine warranty?

Answer: 12 months free for whole machine, After a year, spare parts charges, but life-long free for consultant.

Question: How long is your lead time?

Answer: Depends on the machines you choose. Generally from 7 days to 35days. Some big machine: 45-60days.

Question: How could I know how to operate the machines?

Answer: We provide teaching video and operating manual, and 24 hours in 7 days video guidance.

Question:How long is your machine warranty?

Answer: 12 months free for whole machine, After a year, spare parts charges, but life-long free for consultant.