Email cannot be empty

Password cannot be empty

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

UV Resin Production Line

-

≥1/set

USD 150,000.00

1. Introduction to UV Resin

UV resin is a type of synthetic resin that remains in a liquid state until it is exposed to ultraviolet (UV) light. Upon exposure, it undergoes a rapid chemical reaction called photopolymerization, instantly hardening (curing) into a solid, durable, and clear plastic.

Key Characteristics:

-

Fast Curing: Hardens in seconds or minutes under a UV light source (e.g., UV lamps, or even strong sunlight).

-

Low Volatile Organic Compounds (VOCs): Unlike many epoxy resins, UV resins don't require mixing and have minimal odor and VOCs.

-

Clarity: Cures to a crystal-clear, glass-like finish, making it ideal for coatings and jewelry.

-

Applications: Commonly used for crafts (jewelry, DIY decorations), coatings for electronics and paper, adhesives, and 3D printing (SLA/DLP technologies).

2. Production Steps (Manufacturing Process)

The industrial production of UV resin is a precise chemical process focused on mixing and quality control.

Step 1: Formulation

Chemists design a specific recipe based on the desired final properties (e.g., hard coating for electronics vs. flexible resin for crafts). They select the appropriate types and ratios of oligomers, monomers, and photoinitiators.

Step 2: Pre-Mixing

The main ingredients—oligomers and monomers—are loaded into a large, temperature-controlled mixing tank. They are stirred together to create a homogeneous liquid base.

Step 3: Incorporation of Photoinitiators and Additives

The photoinitiators are carefully added to the mixture. This step is often done under light-controlled conditions (e.g., yellow or red lighting) to prevent the resin from beginning to cure prematurely from ambient UV light. Any additives (stabilizers, pigments, etc.) are also added at this stage.

Step 4: Homogenization and Filtration

The mixture is stirred thoroughly, often for several hours, to ensure every component is perfectly dissolved and distributed evenly. This is critical for consistent performance. The mixture may be passed through a filtration system to remove any undissolved particles or impurities that could cause cloudiness or defects.

Step 5: Quality Control (QC) Testing

Samples are taken from the batch for testing. Key QC tests include:

-

Viscosity: Ensuring it's the right thickness.

-

Cure Speed: Testing how fast it hardens under a standard UV lamp.

-

Clarity/Yellowness Index: Measuring how clear the cured product is.

-

Hardness: Testing the final surface hardness.

Step 6: Packaging

Once the batch passes QC, it is pumped into light-blocking containers (usually amber bottles, foil pouches, or black bottles). This opaque packaging is essential to protect the resin from light during storage and transportation.

3. Raw Materials (The Chemistry Behind UV Resin)

UV resin is a formulated mixture of several key chemical components:

Oligomers

These form the backbone of the resin. They determine the final properties of the cured material, such as flexibility, hardness, and chemical resistance. Common types are Urethane Acrylates (for flexibility and toughness), Epoxy Acrylates (for hardness and chemical resistance), and Polyester Acrylates (for good adhesion).

Reactive Monomers

These chemicals dilute the oligomers to reduce viscosity (make it less thick). They cross-link during curing and also influence the final properties. Common examples include TPGDA (Tripropylene Glycol Diacrylate) for hardness, HDDA (Hexanediol Diacrylate) for good reactivity, and TMPTA (Trimethylolpropane Triacrylate) for high durability.

Photoinitiators

This is the most critical component for UV curing. These molecules absorb UV light energy and break down into reactive species that start the polymerization chain reaction. Common photoinitiators are TPO (Diphenyl(2,4,6-trimethylbenzoyl)phosphine oxide) and Irgacure 184 (1-Hydroxycyclohexyl phenyl ketone).

Additives

These are small amounts added to modify specific properties or enhance performance. They include UV Stabilizers to prevent yellowing, Pigments and Dyes for color, and Inhibitors to prevent premature curing during storage.

TGM Chemical Machine Co., Ltd is a group enterprise. We have brands like TGM, Pengchang and Tongpeng.

We are a leader in the field of chemical machine industry, with 18 years of industry experience.

We have professional R&D design team, strong technical support, skilled production team, reliable after sales service, flexible customized solutions,

to meet your various standards and non standard equipment procurement needs. We committed to providing the complete and professional chemical equipment solutions.

We integrate, design, development, production, sales and training together.

Our products scope: Disperser, Bead Mill, Basket Mill, Mixer, emulsifier, Mixing kettles, Reactor, Filling machine, Bag filter, Pumps, Zirconium Bead, 3 roll mill, and other accessories.

Our machines help you to make ideal products: paints, coatings, inks, pigments, dyes, thinner, hardener, emulsions, varnish, spin finish, putty, glues, adhesives, viscous pastes, concrete Admixtures,

PCVC solvent cement, liquid resins, sealants, silicone sealant, lithium battery, electronic slurry&paste, pulps, silicon dioxide, liquid rubber, pesticide, liquid fertilizer, disinfectant, liquid detergent, gel,

lotions, shampoo, body wash, liquid soap, hand sanitizer, liquid wash, nail polish, creams, and so on.

We could offer individual machine or full production lines for your plants.

5. What are advantages of your factory?

1) Our factory is a leader manufacture of Chemical machine With 18 years of Industry experience. We have a lot Technology Patents & Product Patents;

2) Our factory has Professional R&D Teams, High Technical Supports, Skilled Production Team, Reliable After Sales Service, Flexible Customized Solutions;

3) Our factory is the leader of this industry, named with high and new technology enterprise;

4) Our factory has plenty of industry experience, we could offer you the complete palnt planning.

6. Who are your factory's clients? Could you list some of them?

AKZONOBEL, JUNTON, PPG, NIPPON, DABAO, BURGER, MAYDOS, RAINBOW, HITECH COATING, CHINA PAINT, CHANGJIANG COATING, TOA, LYNWON PIGMENT,

PEONY INKS, TL INKS, ZR INKS, SAKATA INKS, KINGSWOO INKS, DIC INKS, ANLI, ACHILLES, REPOW GROUP, SHINETSU ADHESIVES, JUSHI, XINGLONG PESTICIDES...

7. What certificate your factory could offer?:

CE, BSC, CNEX, ISO, patents.

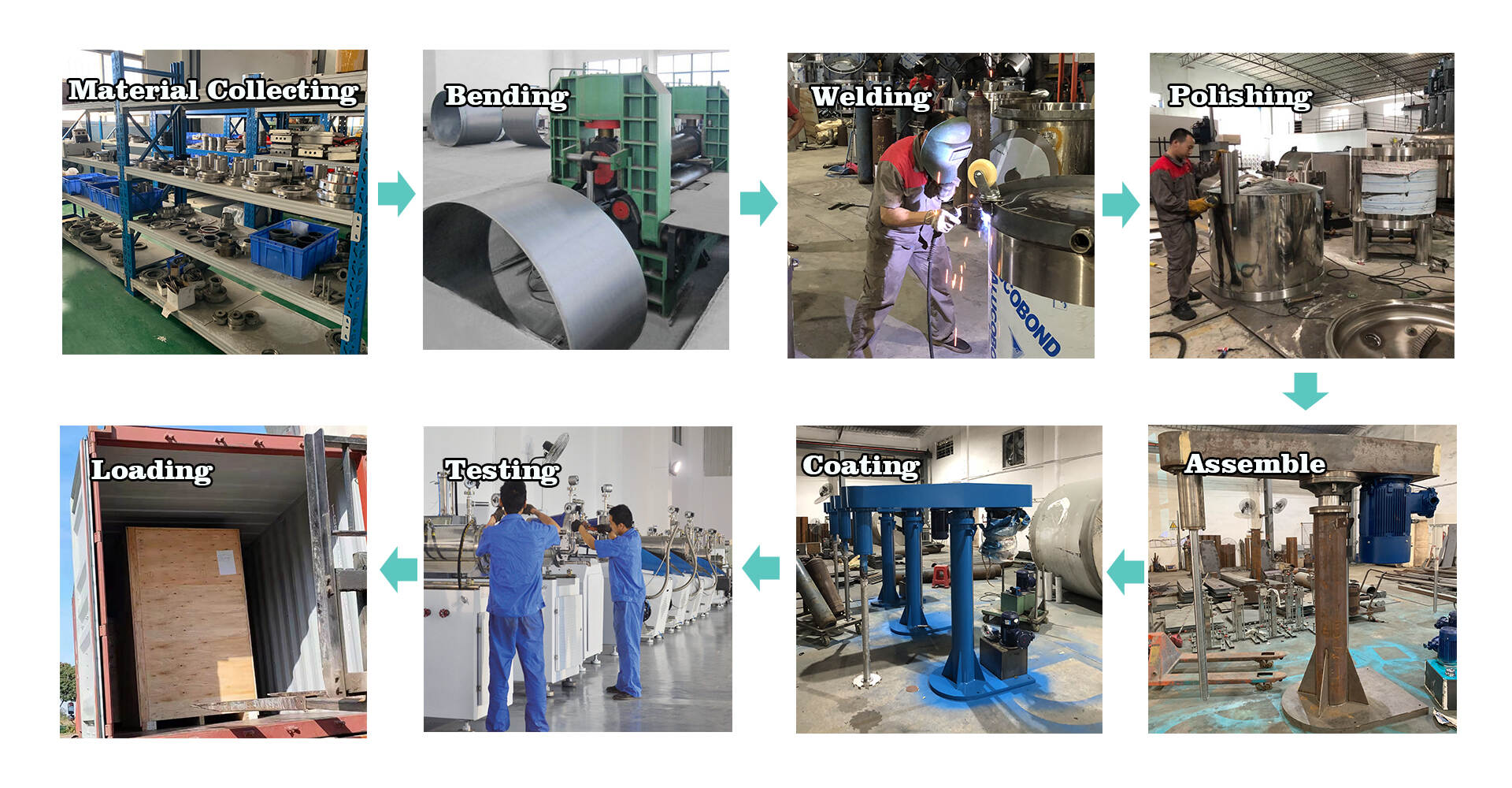

8. Manufacture Processing:

Our Chemical Machines are strictly quality control at every single production step, after quality past, we will move to do next step production.

Our Chemical Machines production process: raw materials preparing-cutting/bending materials-welding-polishing-assembling-coating-testing-packing-loading.

9. Packing And Shipping:

10. FAQ:

Question: Are you a factory or a trading company? where is your factory?

Answer: We are a real factory. Our factory is in fu'an industrial zone, leliu street, shunde ditrict, foshan city, guangdong province, China.

Question: Which countries your machine sold to?

Answer: American Market: America, Canada, Mexico, Brazil;

European Market: UK, Germany, Netherlands, Bulgaria, Italy, Russia;

African Market: South Africa, Algeria, Zambia, Cameroon, Ethiopia, Uganda, Madagascar;

Asian Market: Malaysia, Indonesia, Singapore, Vietnam, Thailand, Kazakhstan, Bangladesh, Pakistan, Lebanon, Iran, Iraq, Egypt, Qatar, Turkey, Saudi Arabia, UAE;

Question: How long is your machine warranty?

Answer: 12 months free for whole machine, After a year, spare parts charges, but life-long free for consultant.

Question: How long is your lead time?

Answer: Depends on the machines you choose. Generally from 7 days to 35days. Some big machine: 45-60days.

Question: How could I know how to operate the machines?

Answer: We provide teaching video and operating manual, and 24 hours in 7 days video guidance.

Question:How long is your machine warranty?

Answer: 12 months free for whole machine, After a year, spare parts charges, but life-long free for consultant.