Email cannot be empty

Password cannot be empty

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Alkyd Resin Production Line

-

≥1/set

USD 150,000.00

1.Introduction to Alkyd Resin

Alkyd resins are polyester-based polymers modified with fatty acids (often from vegetable oils). They are widely used as binders in:

-

Paints & Coatings (architectural, industrial, marine)

-

Printing Inks

-

Adhesives & Sealants

-

Wood Finishes

Alkyd resins offer excellent gloss retention, durability, and brushability, making them ideal for protective and decorative coatings. They can be classified as:

-

Short-oil alkyds (<45% oil content) - faster drying, harder films

-

Medium-oil alkyds (45-55% oil content) - balanced properties

-

Long-oil alkyds (>55% oil content) - slower drying, more flexible

2.Production Process of Alkyd Resin

1. Charging Raw Materials

-

Polyols (glycerol, pentaerythritol), dibasic acids (phthalic anhydride, isophthalic acid), and fatty acids/oils (soybean, linseed, coconut) are loaded into a stainless steel reactor.

-

The reactor is equipped with agitator, heating/cooling system, and condenser.

2. Alcoholysis (for oil-based alkyds)

-

If using vegetable oils instead of fatty acids, alcoholysis is performed first:

-

Oils + polyol (glycerol) → monoglycerides (at 220-250°C with catalyst like LiOH).

-

Reaction monitored by methanol solubility test.

-

3. Esterification (Polycondensation)

-

Dibasic acid (e.g., phthalic anhydride) is added.

-

Heated to 200-250°C under inert gas (N₂/CO₂) to prevent oxidation.

-

Water byproduct is removed via azeotropic distillation (xylene often used as entrainer).

-

Reaction progress tracked by acid value (target: <10 mg KOH/g).

4. Dilution & Adjustment

-

Once desired viscosity/acid value reached, resin is cooled to 150-170°C.

-

Thinned with solvents (mineral spirits, xylene) to 50-70% solids.

-

Additives (driers, antioxidants) are blended in.

5. Filtration & Packaging

-

Filtered through micron filters to remove gels/impurities.

-

Packed in drums or totes for storage/shipping.

3.Raw Materials Needed for Alkyd Resin Production

| Category | Key Materials | Function |

|---|---|---|

| Polyols | Glycerol, Pentaerythritol | Provides hydroxyl groups for esterification |

| Dibasic Acids | Phthalic anhydride, Isophthalic acid | Forms polyester backbone |

| Fatty Sources | Soybean oil, Linseed oil, Coconut fatty acids | Imparts flexibility/weatherability |

| Catalysts | Lithium hydroxide, Tin compounds | Accelerates alcoholysis/esterification |

| Solvents | Xylene, Mineral spirits | Reduces viscosity for application |

| Additives | Cobalt/Zirconium driers, Antioxidants | Controls drying/stability |

4. TGM Factory Profile:

TGM Chemical Machine Co., Ltd is a group enterprise. We have brands like TGM, Pengchang and Tongpeng.

We are a leader in the field of chemical machine industry, with 18 years of industry experience.

We have professional R&D design team, strong technical support, skilled production team, reliable after sales service, flexible customized solutions,

to meet your various standards and non standard equipment procurement needs. We committed to providing the complete and professional chemical equipment solutions.

We integrate, design, development, production, sales and training together.

Our products scope: Disperser, Bead Mill, Basket Mill, Mixer, emulsifier, Mixing kettles, Reactor, Filling machine, Bag filter, Pumps, Zirconium Bead, 3 roll mill, and other accessories.

Our machines help you to make ideal products: paints, coatings, inks, pigments, dyes, thinner, hardener, emulsions, varnish, spin finish, putty, glues, adhesives, viscous pastes, concrete Admixtures,

PCVC solvent cement, liquid resins, sealants, silicone sealant, lithium battery, electronic slurry&paste, pulps, silicon dioxide, liquid rubber, pesticide, liquid fertilizer, disinfectant, liquid detergent, gel,

lotions, shampoo, body wash, liquid soap, hand sanitizer, liquid wash, nail polish, creams, and so on.

We could offer individual machine or full production lines for your plants.

5. What are advantages of your factory?

1) Our factory is a leader manufacture of Chemical machine With 18 years of Industry experience. We have a lot Technology Patents & Product Patents;

2) Our factory has Professional R&D Teams, High Technical Supports, Skilled Production Team, Reliable After Sales Service, Flexible Customized Solutions;

3) Our factory is the leader of this industry, named with high and new technology enterprise;

4) Our factory has plenty of industry experience, we could offer you the complete palnt planning.

6. Who are your factory's clients? Could you list some of them?

AKZONOBEL, JUNTON, PPG, NIPPON, DABAO, BURGER, MAYDOS, RAINBOW, HITECH COATING, CHINA PAINT, CHANGJIANG COATING, TOA, LYNWON PIGMENT,

PEONY INKS, TL INKS, ZR INKS, SAKATA INKS, KINGSWOO INKS, DIC INKS, ANLI, ACHILLES, REPOW GROUP, SHINETSU ADHESIVES, JUSHI, XINGLONG PESTICIDES...

7. What certificate your factory could offer?:

CE, BSC, CNEX, ISO, patents.

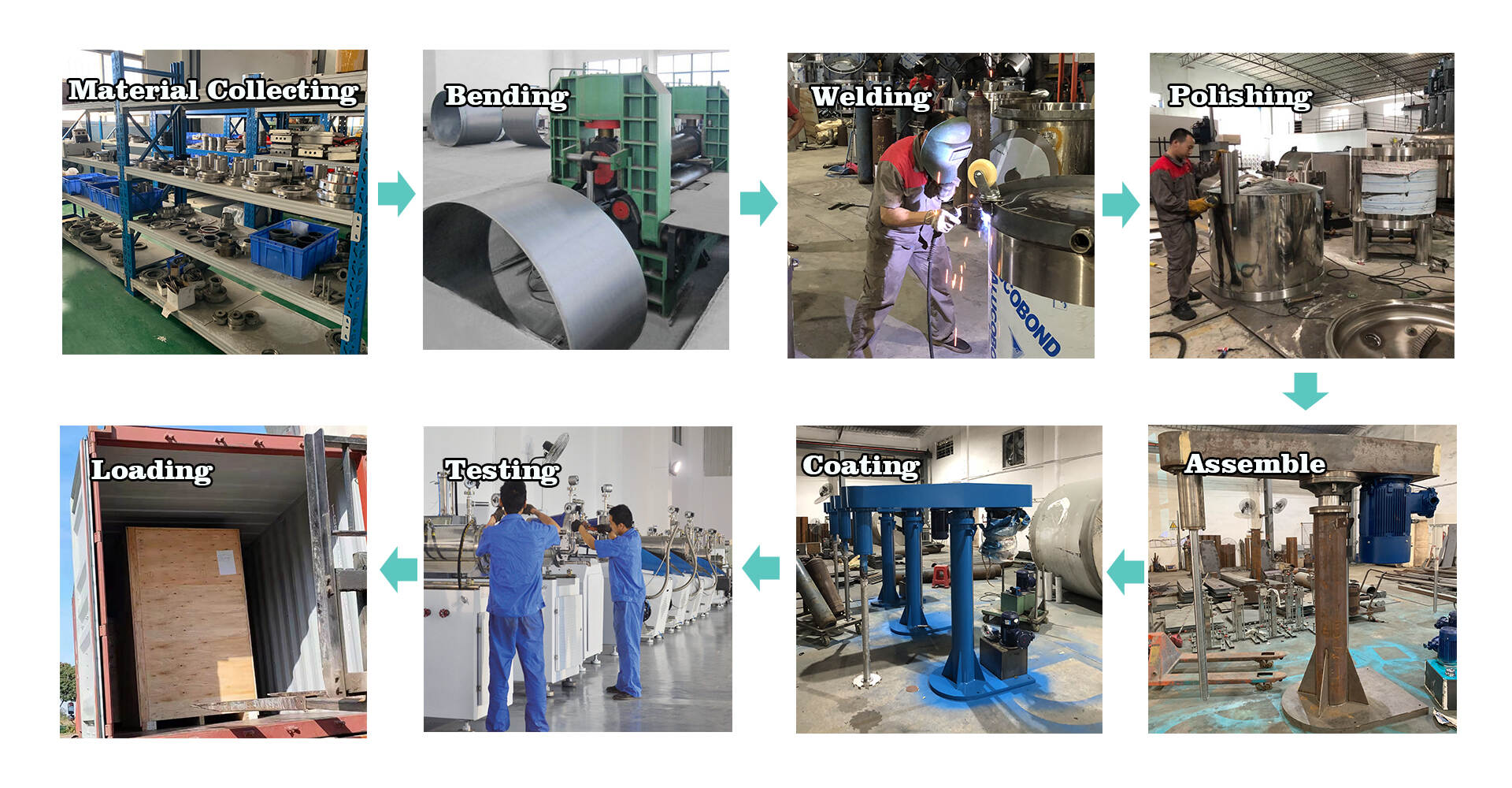

8. Manufacture Processing:

Our Chemical Machines are strictly quality control at every single production step, after quality past, we will move to do next step production.

Our Chemical Machines production process: raw materials preparing-cutting/bending materials-welding-polishing-assembling-coating-testing-packing-loading.

9. Packing And Shipping:

10. FAQ:

Question: Are you a factory or a trading company? where is your factory?

Answer: We are a real factory. Our factory is in fu'an industrial zone, leliu street, shunde ditrict, foshan city, guangdong province, China.

Question: Which countries your machine sold to?

Answer: American Market: America, Canada, Mexico, Brazil;

European Market: UK, Germany, Netherlands, Bulgaria, Italy, Russia;

African Market: South Africa, Algeria, Zambia, Cameroon, Ethiopia, Uganda, Madagascar;

Asian Market: Malaysia, Indonesia, Singapore, Vietnam, Thailand, Kazakhstan, Bangladesh, Pakistan, Lebanon, Iran, Iraq, Egypt, Qatar, Turkey, Saudi Arabia, UAE;

Question: How long is your machine warranty?

Answer: 12 months free for whole machine, After a year, spare parts charges, but life-long free for consultant.

Question: How long is your lead time?

Answer: Depends on the machines you choose. Generally from 7 days to 35days. Some big machine: 45-60days.

Question: How could I know how to operate the machines?

Answer: We provide teaching video and operating manual, and 24 hours in 7 days video guidance.

Question:How long is your machine warranty?

Answer: 12 months free for whole machine, After a year, spare parts charges, but life-long free for consultant.