Email cannot be empty

Password cannot be empty

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Ribbon Mixer

-

200

-

500

-

1000

-

2000

-

3000

-

5000

-

7000

-

10000

industrial mixer for liquid soap, inks mixer, jet ink mixer, mixer body lotion, mixer with scraping

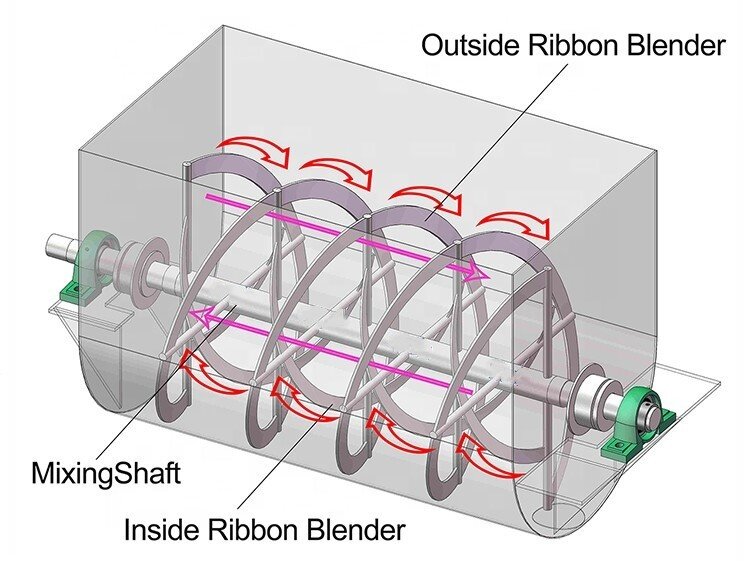

1. Ribbon Mixer Information:

Horizontal ribbon mixer is widely used in chemicals, pharmaceuticals, food, and construction line.

It can be used to mix the powder with powder, powder with liquid, and powder with granules/sands. Under the drive of the motor, the double ribbon agitator mixes the material quickly.

The outer ribbon pushes the material from the two ends to the center, inner ribbon pushes the material from the center to the two ends. Thus to achieve material convention.

The discharging port is set in the bottom center, with the help of the outer ribbon, the material can be discharged completely, and no dead zone.

Material can be carbon steel, manganese steel, ss304, 316L and 321; besides, different material

can also be used in combination. Surface treatment for stainless steel include sandblasting, wiredrawing, polishing, mirror polishing. All can be used in different parts of a mixer.

Options for motor: general motors, explosion-proof motors, variable frequency motor, high efficiency and energy saving motor. Commonly used reducers: R-series, K-series, and F-series gear box; cycloidal reducer, universal gear reducer, planetary gear reducer.Commonly motor-gearbox connection: direct connection, pulley connection, hydraulic coupler connection.

3.High efficiency mixing unit

Different main shaft agitators can be equipped according to the properties of raw materials.

The main shaft agitator could be: inner and outer ribbon, paddle and ribbon, disconnected ribbon, and shaver-shaped agitator.

4.Excellent discharging unit

The drive types of valve are Manual, pneumatic, and electric.Valves for consideration: powder spherical valve, cylinder valve, plum-blossom dislocation valve, butterfly valve, rotary valve etc.

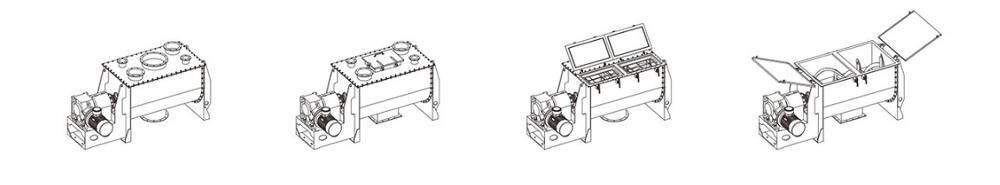

5.Various inlets

Various inlets on the top cover of the barrel can be designed according to different situations.

They can be used as man hole, cleaning door, feeding hole, vent, and dust colleting hole.

The top cover can be designed as fully-opened lid for easy cleaning.

6.Powerful auxiliary components

Mixer is frequently equipped with many auxiliary components, like steam coil jacket, honeycomb pressure jacket, medium circulation jacket,sampling valve, high speed chopper, temperature sensor, weighing system, dust removal system and so on.

Different heat medium requires different jacket, it can be used for heating and cooling, while, the temperature should be within 250 Celsius degree .

2. Ribbon Mixer Specification Details:

| Type | TGM200 | TGM500 | TGM1000 | TGM2000 | TGM3000 | TGM5000 | TGM7000 | TGM10000 |

|---|---|---|---|---|---|---|---|---|

| Main Motor power(kw) | 3 | 4 | 5.5 | 7.5 | 11 | 15 | 18.5 | 22 |

| Main shaft Speed (r/min) | 50 | 50 | 55 | 75 | 75 | 90 | 90 | 100 |

| mixer shaft Speed (r/min) | 21 | 21 | 21 | 21 | 21 | 21 | 21 | 21 |

| Assist Motor power(kw) | / | / | / | 0.75 | 0.75 | 1.5 | 1.5 | 2.2 |

| Production Capacity | 200L | 500L | 1T | 2T | 3T | 5T | 7T | 10T |

3. TGM Factory Profile:

TGM Chemical Machine Co., Ltd is a group enterprise. We have brands like TGM, Pengchang and Tongpeng.

We are a leader in the field of chemical machine industry, with 18 years of industry experience.

We have professional R&D design team, strong technical support, skilled production team, reliable after sales service, flexible customized solutions,

to meet your various standards and non standard equipment procurement needs. We committed to providing the complete and professional chemical equipment solutions.

We integrate, design, development, production, sales and training together.

Our products scope: Disperser, Bead Mill, Basket Mill, Mixer, emulsifier, Mixing kettles, Reactor, Filling machine, Bag filter, Pumps, Zirconium Bead, 3 roll mill, and other accessories.

Our machines help you to make ideal products: paints, coatings, inks, pigments, dyes, thinner, hardener, emulsions, varnish, spin finish, putty, glues, adhesives, viscous pastes, concrete Admixtures,

PCVC solvent cement, liquid resins, sealants, silicone sealant, lithium battery, electronic slurry&paste, pulps, silicon dioxide, liquid rubber, pesticide, liquid fertilizer, disinfectant, liquid detergent, gel,

lotions, shampoo, body wash, liquid soap, hand sanitizer, liquid wash, nail polish, creams, and so on.

We could offer individual machine or full production lines for your plants.

4. What are advantages of your factory?

1) Our factory is a leader manufacture of Chemical machine With 18 years of Industry experience. We have a lot Technology Patents & Product Patents;

2) Our factory has Professional R&D Teams, High Technical Supports, Skilled Production Team, Reliable After Sales Service, Flexible Customized Solutions;

3) Our factory is the leader of this industry, named with high and new technology enterprise;

4) Our factory has plenty of industry experience, we could offer you the complete palnt planning.

5. What Product You Can Produce With Ribbon Mixer:

This high speed disperser if special for producing medicine, spice, fodder, paints, metallurgy, plastic powder, putty powder, ceramic, cosmetics and so on.

6. Who are your factory's clients? Could you list some of them?

AKZONOBEL, JUNTON, PPG, NIPPON, DABAO, BURGER, MAYDOS, RAINBOW, HITECH COATING, CHINA PAINT, CHANGJIANG COATING, TOA, LYNWON PIGMENT,

PEONY INKS, TL INKS, ZR INKS, SAKATA INKS, KINGSWOO INKS, DIC INKS, ANLI, ACHILLES, REPOW GROUP, SHINETSU ADHESIVES, JUSHI, XINGLONG PESTICIDES...

7. Ribbon Mixer Projects showcase:

8. Packing And Shipping:

9. FAQ:

Question 1: Are you a factory or a trading company? where is your factory?

Answer 1: We are a real factory. Our factory is in fu'an industrial zone, leliu street, shunde ditrict, foshan city, guangdong province, China.

Question 2: What certificate your factory could offer?

Answer 2: CE, BSC, CNEX, ISO, patents.

Question 3: What products your machines could make?

Answer 3: Our machines help to make paints, coatings, inks, pigments, dyes, thinner, hardener, emulsions, varnish, spin finish, putty, glues, adhesives,

viscous pastes,concrete Admixtures, PCVC solvent cement, liquid resins, sealants, silicone sealant, lithium battery, electronic slurry&paste,

pulps, silicon dioxide, liquid rubber, pesticide, liquid fertilizer, disinfectant, liquid detergent, gel, lotions, shampoo, body wash, liquid soap, hand sanitizer, liquid wash, nail polish,

creams, and so on.

Question 4: Which countries your machine sold to?

Answer 4: American Market: America, Canada, Mexico, Brazil;

European Market: UK, Germany, Netherlands, Bulgaria, Italy, Russia;

African Market: South Africa, Algeria, Zambia, Cameroon, Ethiopia, Uganda, Madagascar;

Asian Market: Malaysia, Indonesia, Singapore, Vietnam, Thailand, Kazakhstan, Bangladesh, Pakistan, Lebanon, Iran, Iraq, Egypt, Qatar, Turkey, Saudi Arabia, UAE;

Question 5: How long is your machine warranty?

Answer 5: 12 months free for whole machine, After a year, spare parts charges, but life-long free for consultant.

Question 6: How long is your lead time?

Answer 6: Depends on the machines you choose. Generally from 7 days to 35days. Some big machine: 45-60days.

Question 7: How could I know how to operate the machines?

Answer 7: We provide teaching video and operating manual, and 24 hours in 7 days video guidance.

Question 8:How long is your machine warranty?

Answer 8: 12 months free for whole machine, After a year, spare parts charges, but life-long free for consultant.