Email cannot be empty

Password cannot be empty

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

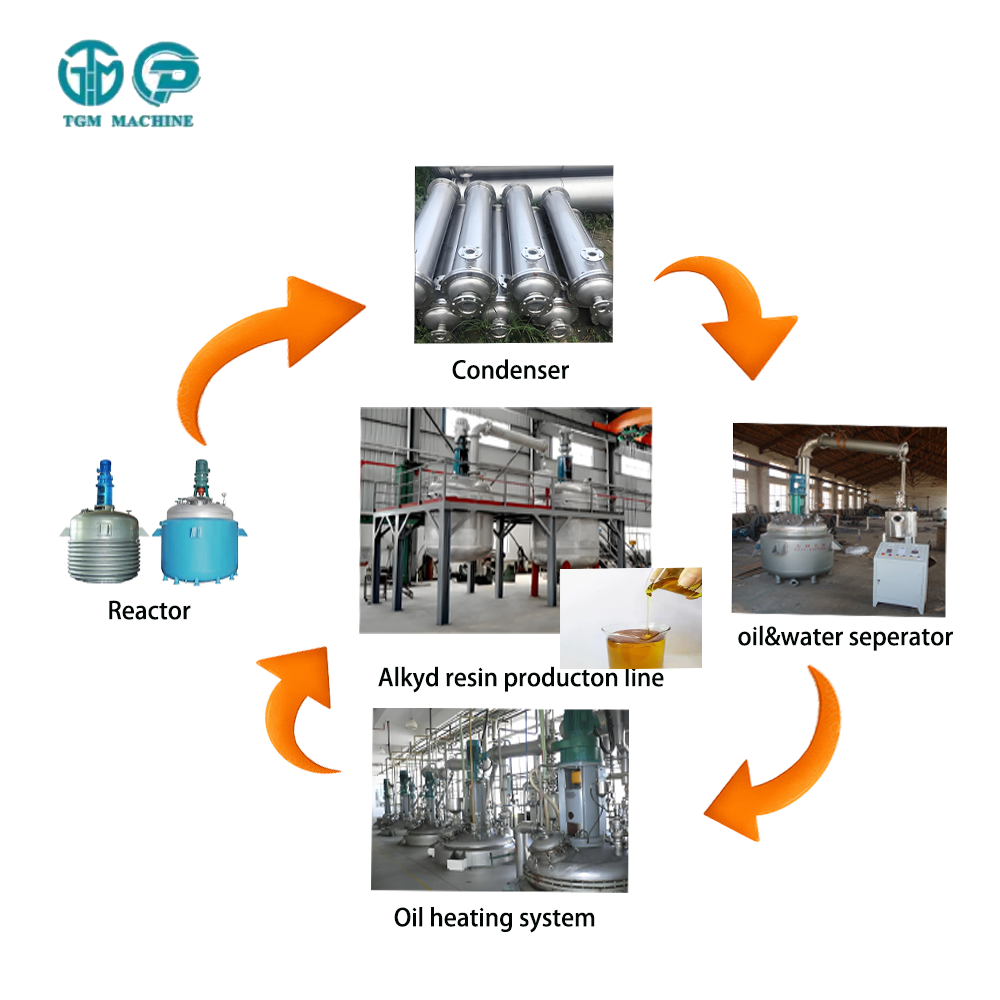

The Production Line of Alkyd Resins: A Comprehensive Overview

Introduction

Alkyd resins are one of the most widely used synthetic polymers in the coatings, paints, and adhesives industries. Their excellent film-forming properties, durability, and versatility make them a preferred choice for various applications. In this blog, we will take a detailed look at the alkyd resin production line, covering the key stages, equipment, and processes involved.

1. Raw Materials for Alkyd Resin Production

The primary raw materials used in alkyd resin manufacturing include:

-

Polyols (e.g., glycerol, pentaerythritol)

-

Polybasic acids/anhydrides (e.g., phthalic anhydride, isophthalic acid)

-

Fatty acids/oils (e.g., soybean oil, linseed oil, coconut oil)

-

Catalysts & additives (e.g., metal driers, antioxidants)

2. Alkyd Resin Production Process

The production of alkyd resins typically follows a batch process in a reactor system. The main steps include:

A. Esterification (Polycondensation) Reaction

-

The polyols, dibasic acids, and fatty acids are charged into a stainless steel or glass-lined reactor.

-

The mixture is heated to 200–250°C under an inert gas (nitrogen) atmosphere to prevent oxidation.

-

A condenser recovers volatile byproducts (e.g., water) to drive the reaction forward.

-

The reaction progress is monitored by acid value and viscosity measurements.

B. Solvent Dilution & Modification

-

Once the desired molecular weight is achieved, the resin is cooled to ~180°C.

-

Solvents (e.g., mineral spirits, xylene) are added to adjust viscosity.

-

Additives (driers, stabilizers) may be incorporated to enhance performance.

C. Filtration & Packaging

-

The final product is filtered to remove impurities.

-

The alkyd resin is then packed into drums or intermediate bulk containers (IBCs).

3. Key Equipment in an Alkyd Resin Production Line

-

Reactor (Stainless steel or glass-lined, with heating/cooling jackets)

-

Condenser (For reflux and byproduct removal)

-

Solvent dosing system (For controlled dilution)

-

Filtration unit (Cartridge or bag filters)

-

Storage tanks & packaging line

4. Quality Control & Testing

To ensure consistency, alkyd resins undergo several tests:

-

Acid value (ASTM D1639)

-

Viscosity (ASTM D2196)

-

Color measurement (Gardner scale)

-

Drying time & film hardness

5. Applications of Alkyd Resins

-

Paints & coatings (architectural, industrial, marine)

-

Printing inks

-

Adhesives & sealants

-

Wood finishes

Conclusion

The alkyd resin production line is a carefully controlled process that balances chemical reactions, solvent management, and quality assurance. With advancements in bio-based raw materials and low-VOC formulations, alkyd resins continue to evolve as a sustainable solution for the coatings industry.

If you want to know more about Alkyd Resin production Line ,feel free to tell me.